2026 Top Injection Molding Machine With Robot Trends?

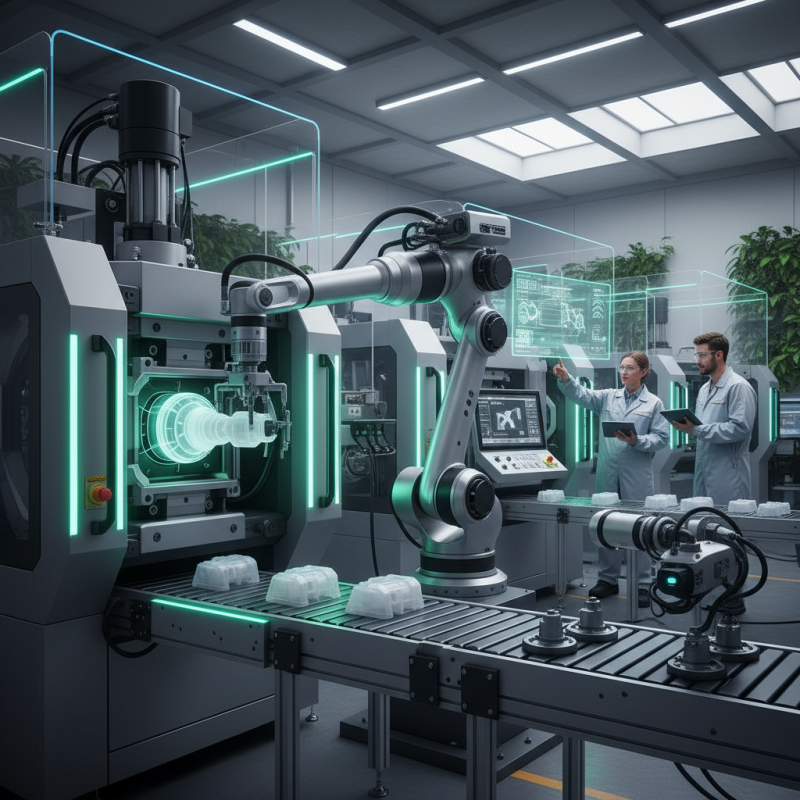

In the rapidly evolving landscape of manufacturing, the "Injection Molding Machine With Robot" sector stands at the forefront of innovation. Industry expert Dr. Emily Chen highlights, "Automation is reshaping how we approach production efficiency." This sentiment encapsulates the shift toward integrating robotics into injection molding processes, which enhances precision and reduces cycle times.

As we look ahead to 2026, several trends emerge. Sustainable practices are gaining traction. Manufacturers are exploring eco-friendly materials and energy-efficient machines. The incorporation of artificial intelligence into robotic systems also shows potential. However, challenges remain in the adaptability of existing machinery and training personnel for advanced operations.

These developments are crucial. Companies must thoughtfully adapt to harness the full benefits of an "Injection Molding Machine With Robot." Nevertheless, firms should reflect on their current practices. In the race for modernization, it’s vital not to overlook the human element in this automated future.

2026 Injection Molding Machine Overview and Market Landscape

As we dive into the injection molding machine landscape of 2026, the focus shifts towards technology integration and automation. The market is witnessing a surge in the adoption of robotic systems alongside injection molding machines. These robots enhance precision, speed, and efficiency in production. Many manufacturers are now exploring collaborative robots, or cobots, which work closely with human operators. The use of advanced sensors and artificial intelligence is becoming more common.

The demand for sustainable practices is also reshaping the market. Companies prioritize energy-efficient machines to reduce operational costs. There is a growing emphasis on materials that minimize environmental impact. Products must meet higher sustainability standards. While these advancements are promising, challenges remain. Not all manufacturers can afford these innovations. Some may struggle to keep pace with the rapid changes. Thus, ongoing training and adaptation in the workforce are essential as companies transition to smarter systems. The balance between cost, efficiency, and technological advancement will define the industry's future.

Advancements in Robotic Integration for Injection Molding

Robotic integration has transformed injection molding in recent years. Automation streamlines production processes. Robots now handle complex tasks like part assembly and quality control. This enhances efficiency and reduces human error.

Today's injection molding machines come with advanced robotic features. They can sort, pack, and even perform secondary operations. These machines reduce cycle times and increase output. However, the learning curve remains challenging for many operators. Skills gaps can slow down adaptation.

Still, the potential for growth is significant. Companies are exploring AI-driven robotics for better decision-making. Collaborative robots are becoming popular in workshops. They work alongside human operators, sharing tasks. Yet, safety concerns must be addressed. Investing in training is essential for comprehensive integration.

Key Trends in Automation and Efficiency for 2026

The landscape of injection molding machines is rapidly evolving, mainly driven by automation trends. In 2026, we are likely to see machines integrated with robotic arms more than ever. These robots will not only handle repetitive tasks but also improve precision. Imagine a robot picking and placing parts with speed and accuracy, reducing human error. This efficiency is crucial in competitive markets.

Efficiency in production processes will be paramount. Real-time data analytics will emerge as a key feature. Machines equipped with sensors can monitor performance continuously. This constant feedback loop allows for quick adjustments, minimizing downtime. However, it's essential to consider the challenges. Not all facilities will be ready for such advanced technology. Adapting existing workflows can be a headache.

Another intriguing trend involves energy efficiency. Reducing energy consumption can lead to significant cost savings. Innovative designs in machines will focus on lower energy use without sacrificing output. Yet, companies must assess the initial investment carefully. Transitioning to energy-efficient models requires budget adjustments. It’s a balance between upfront costs and long-term benefits that needs thoughtful consideration.

Impact of Smart Technologies on Injection Molding Processes

The impact of smart technologies on injection molding processes is profound. Automation is reshaping how manufacturers operate. Smart sensors can monitor machine performance in real-time. They track temperature, pressure, and cycle times. This data helps in making informed decisions. Increased efficiency can lead to reduced waste. However, implementation can be challenging.

Integration of robots into molding systems adds another layer of complexity. Robots can handle delicate parts with precision. Yet, they require careful programming and regular maintenance. Mistakes in robotics can lead to product defects. Therefore, operators must stay vigilant. Training is essential to navigate this new terrain effectively.

While smart technologies offer benefits, challenges remain. The transition to automated systems is not always smooth. There can be resistance from workers who fear job loss. Balancing technology and human skill is crucial. Continuous learning and adaptability will determine success in the future of injection molding.

2026 Injection Molding Machine Trends: Impact of Smart Technologies

Sustainability and Eco-Friendly Innovations in Injection Molding

The injection molding industry is undergoing significant changes driven by sustainability. Eco-friendly materials are being developed to replace traditional plastics. Biodegradable options are gaining traction. These innovations reflect a growing awareness of environmental impact.

Robotic integration in injection molding also addresses sustainability. Robots can optimize production efficiency, reducing waste. However, it raises questions about energy use. Are these technologies truly green? Some may still be energy-intensive. The balance between efficiency and sustainability must be critically examined.

Adopting recycled materials is another compelling trend. While it often requires adjustments in machinery, the environmental benefits are considerable. Yet, the challenge remains in sourcing high-quality recycled materials. The industry must collaborate to improve these processes. Strides are being made, but a perfect solution is still on the horizon.

2026 Top Injection Molding Machine With Robot Trends - Sustainability and Eco-Friendly Innovations in Injection Molding

| Trend | Description | Impact on Sustainability | Eco-Friendly Innovations |

|---|---|---|---|

| Energy-Efficient Machines | Machines designed to minimize energy consumption during production. | Reduces carbon footprint and operational costs. | Implementation of servo motors and optimized cooling systems. |

| Biodegradable Materials | Utilization of eco-friendly polymers that decompose effectively. | Lowers plastic waste impact on the environment. | Incorporation of PLA and other plant-based materials. |

| Closed-Loop Systems | Systems designed to recycle waste produced during molding processes. | Minimizes waste and promotes a circular economy. | Installation of recycling units within manufacturing processes. |

| Smart Manufacturing | Integration of IoT and AI in production lines to optimize efficiency. | Enhances resource management and reduces waste. | Use of data analytics for process improvement. |

| Automation and Robotics | Incorporating robotic arms for precision and consistency. | Improves efficiency and reduces manual excess energy consumption. | Robots designed with eco-friendly features and low energy costs. |