How to Choose the Best Alloy Powder Grader for Your Needs?

Choosing the right Alloy Powder Grader can be challenging. The market is filled with options, and each one claims superiority. As Dr. Ethan Pierce, a renowned expert in powder metallurgy, once said, "Finding the right Alloy Powder Grader requires more than just price comparisons."

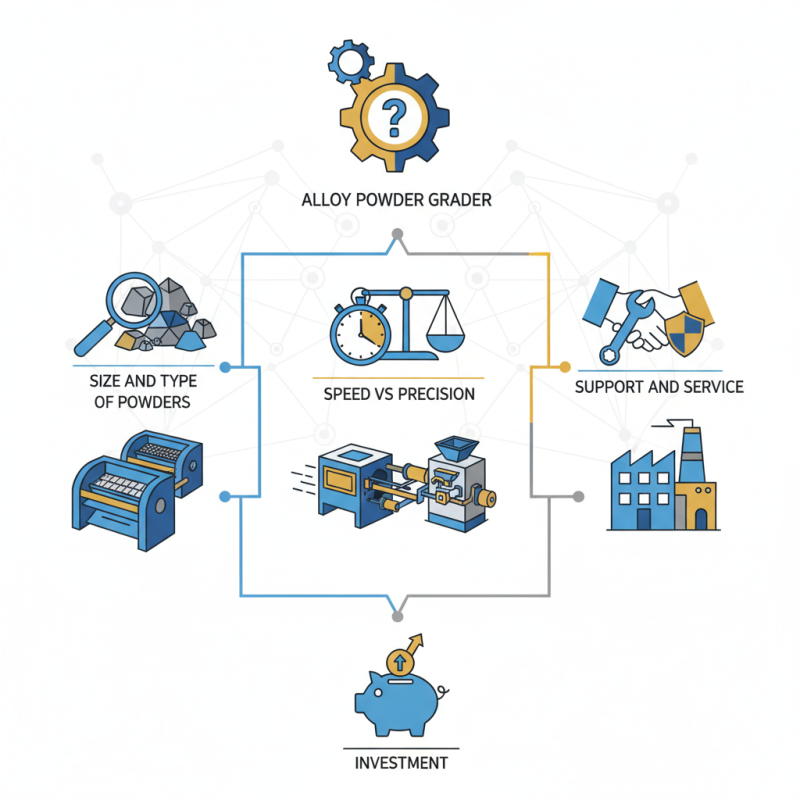

Understanding your specific needs is crucial. Consider the size and type of alloy powders you'll be working with. Different graders suit different materials. Some equipment excels in speed, while others focus on precision. Be clear about your priorities.

Additionally, reflect on the support and service offered by manufacturers. Quality machines are crucial, but so are the relationships with suppliers. It's easy to overlook after-sales service, but it greatly impacts your operations. Remember, an Alloy Powder Grader is an investment. Make your choice wisely.

Understanding the Purpose of Alloy Powder Graders

Alloy powder graders play a crucial role in the manufacturing process. They ensure the right particle size distribution for various applications. The precision of these devices affects the final product quality significantly.

When selecting a grader, it’s important to understand its purpose. Graders separate powders into different size classes. This helps in achieving consistent material properties. A well-functioning grader enhances the efficiency of production. However, it can be challenging. The right calibration is often overlooked. Miscalibrated machines can lead to poor results.

Consider the material you’re working with. Some powders may require specific grading techniques. Others can be less forgiving. Not all graders work well with every alloy. Take time to assess your needs. Find a grader that adapts to your requirements. This decision can affect the entire process flow. Sometimes, trial and error is necessary to get it right.

Key Features to Consider When Selecting an Alloy Powder Grader

When selecting an alloy powder grader, consider the material properties that best fit your application. The grading process hinges on particle size distribution. For example, industry standards often require specific sizes for titanium alloys. Reports indicate that size variations can impact final product strength and durability. Focusing on this aspect helps narrow your choices.

Another critical factor is the grading method employed. Some graders utilize laser diffraction, while others favor sieve analysis. Data shows that laser methods often yield faster results. Yet, sieve analysis remains reliable for certain materials. Evaluating these methods helps ensure that you select a grader suited to your accuracy needs.

Precision is not the only concern. Cost-effectiveness plays a role too. Cheaper graders might compromise on precision, leading to potential inefficiencies downstream. Regular calibration and maintenance can mitigate inaccuracies. However, maintenance increases operational costs. Balancing these aspects is crucial for optimizing production efficiency without overspending.

Evaluating Different Types of Alloy Powder Graders Available

When choosing an alloy powder grader, understanding its types is crucial. There are several options, each with unique features. For instance, gravity-based graders are common. They rely on the material's density and can handle various alloy powders. Their simplicity is an advantage, but they may lack precision in fine particle separation.

Centrifugal graders offer a different approach. They utilize rotation to separate materials based on density and size. This method typically provides a better separation efficiency. However, these machines can be more complex to operate and maintain. Additionally, they require regular calibration to ensure accuracy.

Another option is air classifiers, which use airflow to sort particles. They are great for achieving precise classification, especially for lightweight powders. Still, the setup can be challenging and might need adjustments for optimal performance.

Evaluating your specific needs and the characteristics of each grader type will help you make an informed choice.

Assessing Your Specific Needs and Requirements for Grading

Choosing the right alloy powder grader requires a deep understanding of your specific needs. Start by identifying the range of materials you'll be grading. Are you working with fine powders, or do you need to handle larger particles? This basic difference can drastically affect your choice. Be clear about the type of alloys as well. Not all graders handle every material effectively.

Consider the grading accuracy you require. Some projects demand a tight tolerance for particle size. In contrast, others may allow for a broader range. This precision level can impact the production process directly. A personal experience comes to mind. I once selected a grader that was too broad in its specifications. It caused inconsistencies in my work.

Evaluate the volume of production too. Are you grading small batches or large quantities? Larger volumes might demand more robust equipment. Also, think about the layout of your workspace. Will the grader fit well in your existing setup? These thoughts may seem trivial, yet they can lead to unexpected issues later. Reflecting on these factors will lead you closer to a suitable choice.

Alloy Powder Grader Selection Criteria

This bar chart illustrates the importance rating for various criteria when choosing an alloy powder grader. Each category is rated on a scale from 1 to 10, indicating how critical each factor is to meeting specific grading needs.

Budgeting for Your Alloy Powder Grader Investment

When budgeting for an alloy powder grader, you should consider several factors. Quality is crucial. You may compromise on features, but not on performance. A cost-effective grader can save you money, but it might lack durability. Think about the long-term cost of ownership. More expensive models often offer better warranties and service options.

Research is key. Compare various models within your budget. Look at reviews and user experiences. Some products claim to be affordable but may not meet your needs. Small savings could lead to larger costs later. Factor in maintenance costs too, as they can add to your expenses over time.

Understand your specific requirements. Do you need precision and speed? Will you use it for industrial purposes or smaller projects? Identifying your needs can help guide your budget. Sometimes, spending a bit more upfront can be wise. Choose thoughtfully. Weigh the pros and cons. Be ready to reassess if necessary.