How to Choose the Best Electric Ball Valves for Your Needs?

In the world of fluid control, Electric Ball Valves stand out as crucial components. They provide precise flow regulation and efficiency in a wide range of applications. Expert Andrew Stevens, a leading figure in fluid automation, once stated, “Choosing the right Electric Ball Valves can significantly enhance system performance.” This emphasizes the weight of making an informed decision.

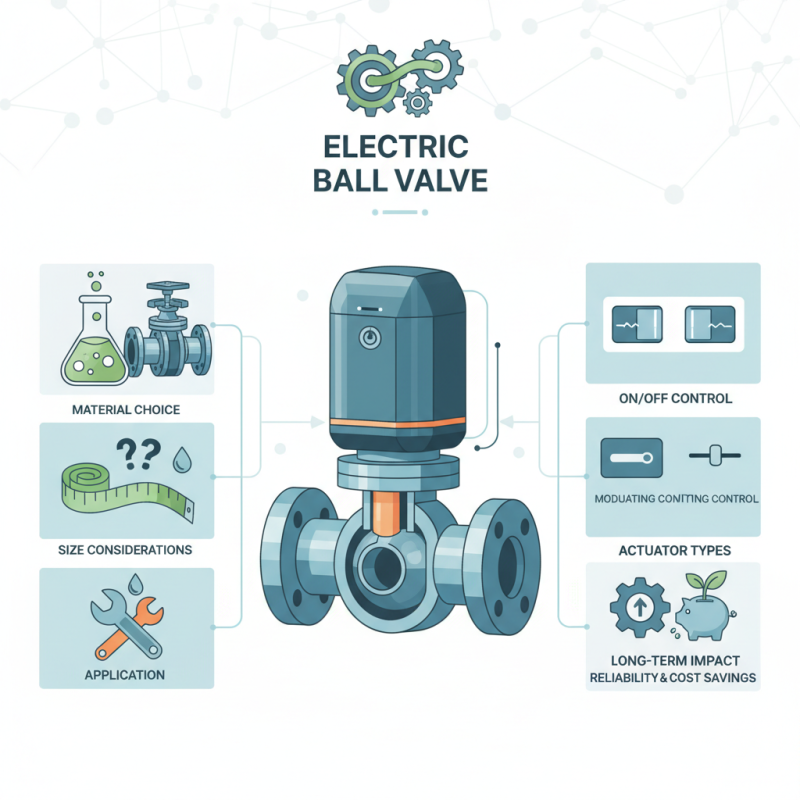

When selecting Electric Ball Valves, one must consider factors like material, size, and application. A stainless steel valve may be perfect for corrosive fluids, while a plastic valve might suffice for less demanding environments. However, consumers often overlook these details. It's easy to assume one size fits all, but this is rarely the case.

Additionally, understanding actuator types can be challenging. Not all electric actuators offer the same performance. The choice between on/off or modulating control can define operational efficiency. Many buyers underestimate the long-term impact of their selection. Making a thoughtful choice can lead to better reliability and lower maintenance costs in the future.

Factors to Consider When Choosing Electric Ball Valves

When selecting electric ball valves, several crucial factors should be considered. The size of the valve plays a significant role. It must fit precisely with your piping system, ensuring a leak-free connection. Consider the flow rate and pressure requirements for your application. If these are not matched properly, you could face severe operational issues.

Another important factor is the material of the valve. Different environments may require valves made from specific materials to resist corrosion or temperature fluctuations. Plastic valves may suffice for low-pressure applications, but metal ones are often necessary for demanding conditions. Additionally, pay attention to the control features. Some valves come with preset options, while others allow for customizable control. This difference impacts ease of use and efficiency.

Don’t overlook the valve's power requirements and compatibility with your system’s technology. Understanding whether the valve can operate on existing power sources is vital. A mismatch here can complicate installation and lead to additional costs. Lastly, regularly review your choices. Technology evolves, and what may have been the best option a few years ago may no longer be ideal. Balancing these factors will guide you to the right decision.

Understanding the Different Types of Electric Ball Valves Available

When selecting an electric ball valve, understanding the different types available is essential. Electric ball valves come in various configurations. Each type serves specific purposes. There are two-way and three-way valves. Two-way valves control flow in one direction. Three-way valves can redirect flow between two different paths. This can be useful for mixing or diverting fluids.

Consider the valve's materials. Stainless steel valves offer durability. They handle high pressures and corrosive substances well. Plastic valves are lighter and cheaper. However, they may not withstand extreme conditions. It’s vital you assess your system requirements before making a choice.

Tips: Check the compatibility of the valve with your existing piping system. An incompatible valve may lead to leaks or failures. Always prioritize quality over price. Sometimes, a cheaper option can cost more in repairs down the line. Researching your options can save you money and headaches later.

Key Technical Specifications for Electric Ball Valves

When selecting electric ball valves, key technical specifications should be your primary focus. Consider factors like valve size, voltage requirements, and materials used. The valve's size must match the pipe diameter to ensure proper flow. According to industry data, incorrect sizing can reduce efficiency by up to 30%.

The voltage specification, usually 24V or 120V, impacts installation. If your system operates at an unusual voltage, finding a compatible valve can be challenging. Additionally, the material matters. Stainless steel offers durability but may cost more. Plastic valves are lighter and less expensive, yet they can wear out faster under high pressure.

Tips: Always check if the valve's specifications align with your application. Understand the pressure class of the valve. It is vital for safety and efficiency. Regular maintenance is also necessary; wear and tear could lead to leaks.

Quality does vary across different products. Always consult industry reviews and user feedback to gauge long-term performance. When in doubt, seeking expert advice can save costs down the line. Consider not only the purchase price but also the maintenance requirements. Your final choice can significantly influence operational efficiency.

Evaluating the Performance and Efficiency of Electric Ball Valves

When evaluating the performance and efficiency of electric ball valves, several key factors stand out. Flow capacity is crucial. According to industry reports, electric ball valves can achieve flow coefficients ranging from 1.0 to 10.0. This variation can significantly impact energy consumption and overall system efficiency. High-performance models often exhibit lower pressure drops. This feature translates into reduced energy costs and longer equipment lifespan.

Response time is another critical aspect. Many electric ball valves provide a response time between 2 to 10 seconds. This speed can influence process stability. However, inconsistencies can arise in systems with varying operational conditions. Monitoring these factors ensures optimal performance. Additionally, energy consumption data reveals that some models use less than 5 watts during operation. This efficiency helps in lowering operational costs.

As with any technology, electric ball valves come with challenges. Installation must be precise. Any misalignment might lead to inefficiencies. User feedback indicates that maintenance can also be subjective. Some users report difficulty in accessing certain components, which can hinder timely repairs. Understanding these nuances is vital for making informed decisions. The balance between performance and maintenance needs careful consideration.

Performance Comparison of Electric Ball Valves

Cost Analysis: Budgeting for Electric Ball Valves in Your Projects

When budgeting for electric ball valves, it's crucial to consider various factors. The initial cost of the valve itself can vary widely. Prices can range from affordable options to high-end products, depending on features and materials. It's important to assess your specific project needs. Sometimes, the cheaper option seems appealing, but it may lack durability.

Installation costs also play a significant role in your budget. Hiring skilled labor may increase expenses, especially for complex systems. Unexpected issues might arise during installation, leading to additional costs. Allocating a buffer for these surprises is wise. For some projects, the total expense may escalate, causing potential delays. Planning for contingencies matters.

Maintenance is another aspect that often goes overlooked. Electric ball valves do require regular checks, and neglecting them can lead to failures. Over time, these failures can add unforeseen costs to your overall project. A comprehensive budget should include potential maintenance and replacement costs. While it might feel daunting, a well-planned budget can save you from future headaches.