How to Choose the Best Vacuum Lifter for Stone Slabs?

Choosing the right vacuum lifter for stone slabs is crucial for efficiency and safety. A vacuum lifter for stone slabs can significantly reduce the risk of injury while enhancing productivity. Many options exist, but not all are suitable for every project.

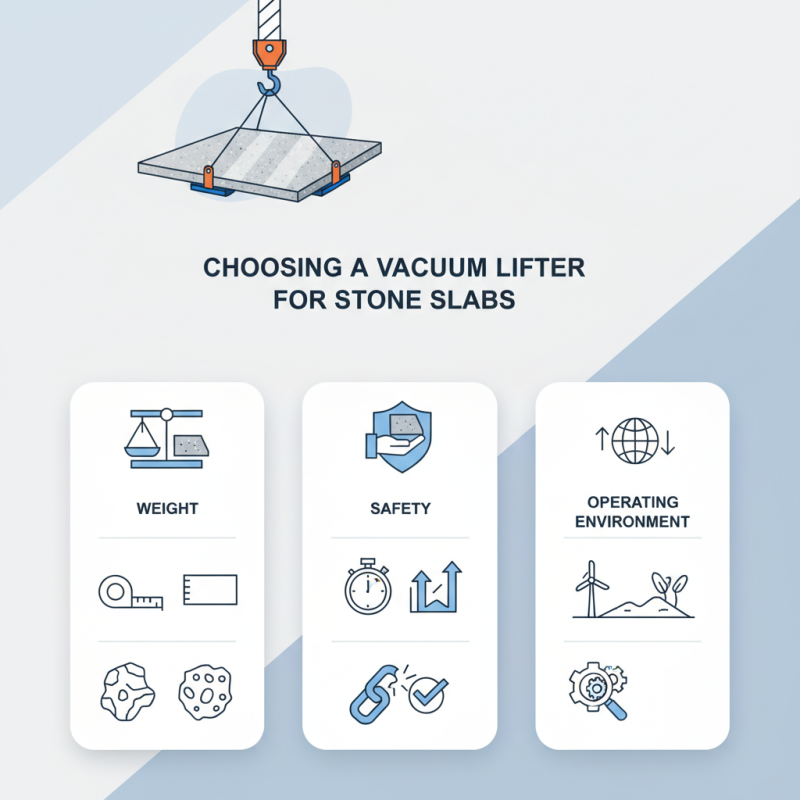

Consider the weight and size of your stone slabs. It is essential to match these specifications to the lifter’s capability. A lifter that cannot handle the load may lead to accidents and costly damage. Additionally, evaluate the type of stone you are working with. Certain materials require specific lifting techniques to avoid breakage.

It is also important to reflect on your operating environment. An outdoor site may present challenges like uneven surfaces or wind. Not all vacuum lifters perform well under these conditions. Investing time in selecting the right equipment can save resources long-term. Thus, research and evaluate your choices carefully.

Understanding the Different Types of Vacuum Lifters for Stone Slabs

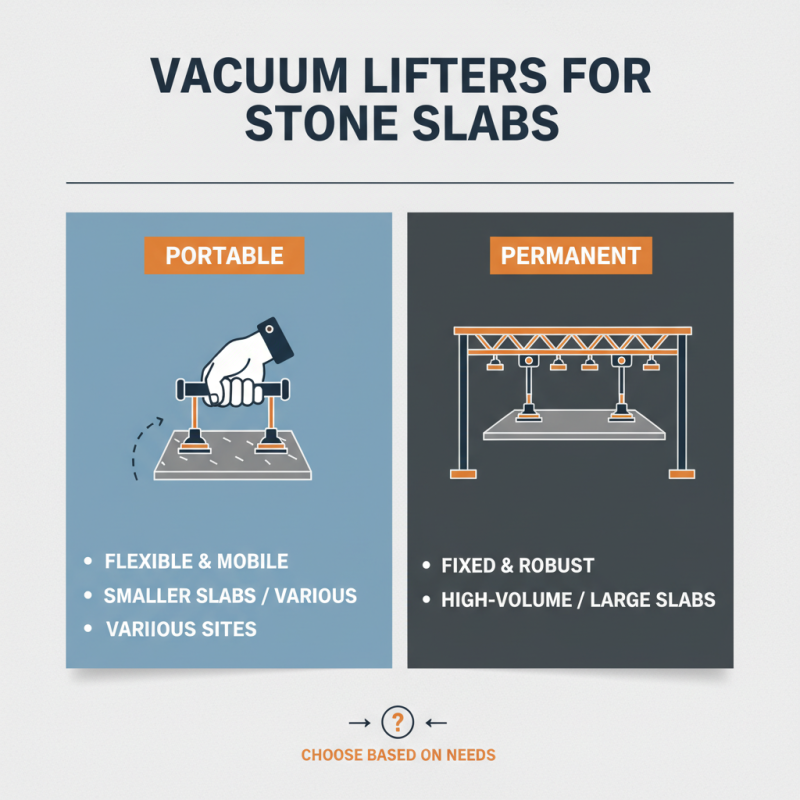

When choosing a vacuum lifter for stone slabs, understanding the types available is crucial. There are two main categories: portable and permanent vacuum lifters. Portable models provide flexibility and are easy to move between job sites. They are handy for smaller slabs. Permanent vacuum lifters are typically fixed and best for high-volume tasks. Each has distinct advantages based on your needs.

Consider capacity when selecting your vacuum lifter. Different models handle varying weights. Always check the maximum weight guide. A lifter may struggle with heavier stones. This can cause accidents or damage.

**Tip:** Always test the suction. Apply the vacuum lifter to a demo slab. Monitor for any slippage during the lift. This will reveal potential issues beforehand.

Keep in mind the surface quality of your stone slabs. Smooth surfaces guarantee better suction. However, textured or uneven surfaces may require specialized lifters. Ensure the model you choose can adapt to these variations.

**Tip:** Evaluate the sealing mechanism. The seal ensures effective lifting. Poor seals lead to failures and can pose serious risks. Always inspect your equipment regularly.

Key Factors to Consider When Choosing a Vacuum Lifter

Choosing the best vacuum lifter for stone slabs requires careful consideration of key factors. The weight capacity is crucial. Ensure the lifter can handle the specific stone thickness and size you're working with. A mismatched lifter may lead to accidents or damage.

Another factor is the vacuum's suction power. Strong suction is essential for safety. Test the lifter before use in real applications. A minor slip could have serious consequences. Consider the surface texture of the stone as well. Smooth stones may require different handling than rough ones.

**Tips:** Always check the manufacturer's specifications. Don't rely solely on reviews. Sometimes, user experiences differ from what is advertised. It's beneficial to seek recommendations from professionals who have used vacuum lifters. Evaluate your unique working conditions closely. Запомните, a tool that works perfectly for one project may be inadequate for another.

How to Choose the Best Vacuum Lifter for Stone Slabs

Evaluating the Weight Capacity and Size of Vacuum Lifters

When choosing a vacuum lifter for stone slabs, weight capacity and size are crucial factors. Stone slabs can weigh significantly, depending on the type and thickness. A vacuum lifter must support the weight of the slabs it will handle. Look for machines that offer a capacity that exceeds the weight of your heaviest slabs. Misjudging this could lead to accidents or damage. It's essential to check your lifting needs carefully.

Size is equally important. The dimensions of the vacuum lifter should match the slabs. A lifter that is too small may not fully grip the slab. This can lead to instability during lifting. On the other hand, a lifter that is excessively large might be cumbersome and difficult to maneuver. Taking precise measurements of the slabs is vital. Consider the thickness as well. If a lifter cannot accommodate the thickness, it may fail to create an adequate seal.

Before making a final decision, consider testing different models. Real-world experience often reveals gaps in specifications. Don't overlook user feedback. Understanding how a lifter performs can provide valuable insights. Patience is key in this selection process. Finding the right vacuum lifter is not just about numbers; it’s about ensuring safety and efficiency on the job.

How to Choose the Best Vacuum Lifter for Stone Slabs? - Evaluating the Weight Capacity and Size of Vacuum Lifters

| Model | Weight Capacity (lbs) | Lifting Area (sq. ft) | Power Source | Vacuum Pump Type |

|---|---|---|---|---|

| Model A | 600 | 4 | Electric | Rotary |

| Model B | 800 | 5 | Battery | Diaphragm |

| Model C | 1000 | 6 | Electric | Rotary |

| Model D | 1200 | 8 | Compressed Air | Diaphragm |

| Model E | 1500 | 10 | Electric | Rotary |

Assessing the Quality and Material of Vacuum Lifters

When selecting a vacuum lifter for stone slabs, quality and material are crucial factors. Look for lifters made from durable materials, like aluminum or high-grade steel. These materials ensure longevity and reliability. A vacuum lifter should withstand the weight and shape of the stone slabs without compromising performance.

Pay attention to the suction pad design. The pads should be made of robust rubber or silicone. They need to create a strong seal on various surfaces. A strong seal prevents slippage during lifting. Test the pads on different stone types before committing.

Tips: Always check the weight capacity before purchase. Make sure it exceeds the slab's weight for safety. Also, consider the lifter's ease of use. If the design is complicated, it may lead to mistakes or accidents. Regular maintenance is key. Inspect for wear and replace parts as needed to ensure longevity.

Importance of Safety Features in Vacuum Lifters for Stone Slabs

When choosing vacuum lifters for stone slabs, safety features must be a top priority. According to a recent industry report, accidents involving heavy lifting equipment account for 18% of workplace injuries. Vacuum lifters designed specifically for stone handling significantly reduce these risks. They provide a secure grip, preventing a slab from slipping during transportation. The right model will have features like dual circuit systems, providing redundancy in case of a failure.

Inadequate safety measures can lead to catastrophic consequences. A study from the Occupational Safety and Health Administration reveals that falls and dropped loads can cause serious injuries or fatalities. Essential features such as visual and audible alarms can alert operators in case of malfunction. Moreover, a well-designed vacuum lifter should come with easy-to-use controls, minimizing the chance of operator error. User training is also pivotal; many operators overlook the importance of proper usage.

Operators should regularly inspect their equipment. This can often be neglected, leading to unforeseen issues. Regular audits and checklists can help, but they require diligence. It's essential to stay informed about the evolving standards and regulations related to lifting equipment. Investing in vacuum lifters with robust safety features not only protects workers but also promotes efficiency in operations.

Related Posts

-

The Comprehensive Handbook to Choosing the Best Stone Lifting Equipment for Your Business Needs

-

Unlocking Efficiency in Manufacturing with the Best Sheet Lifters and How to Choose the Right One

-

China's Best Glass Lifter Revolutionizing Quality Standards and Earning Global Respect

-

Elevating Global Standards: The Excellence of Chinese-Made Lifting Equipment Inspection

-

Transforming Industries: Real-World Success Stories of Best Equipment Inspection Applications

-

Innovative Advancements in Best Chain Hoists Technology Trends for 2025 Guide