What is an Injection Machine Robot and How Does it Work?

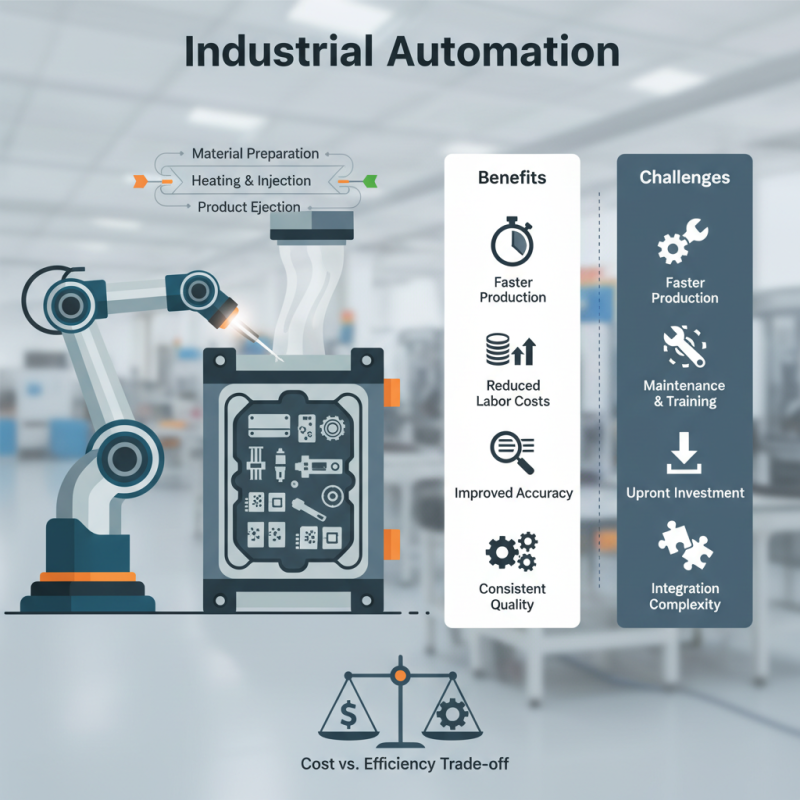

An Injection Machine Robot is a sophisticated device used in the manufacturing industry. It automates the process of injecting materials into molds. This technology has revolutionized production methodologies, making them faster and more efficient.

These robots operate by controlling the injection of liquid materials, often plastics, into molds. This process begins with precise measurements and heating to ensure proper consistency. The Injection Machine Robot is known for its accuracy and repeatability. This precision is crucial for maintaining product quality.

However, challenges remain in the integration of these robots. Companies must invest in training and maintenance to optimize performance. The technology can be costly upfront, yet it potentially reduces labor costs over time. Reflection on these trade-offs is important for manufacturers considering automation.

Overview of Injection Machine Robots and Their Applications

Injection machine robots have transformed the manufacturing landscape. They play a crucial role in various industries, from automotive to consumer goods. By automating the injection molding process, these robots enhance productivity and precision. According to a recent industry report, the global market for injection molding machines is expected to reach $30 billion by 2028. This growth highlights the rising demand for efficient manufacturing solutions.

These robots excel in applications that require high repeatability. They can produce complex parts with intricate designs. For instance, the automotive sector benefits greatly from their ability to create lightweight components. However, challenges remain. The integration of injection machine robots can be costly. Smaller manufacturers might struggle to adopt this technology fully. Moreover, skilled labor is needed to operate and maintain these systems effectively.

In the consumer goods industry, injection machine robots are used to produce everyday items like containers and packaging materials. The precision offered can reduce material waste, aligning with sustainability goals. Yet, the long-term impact on employment in manual labor roles raises questions. As automation increases, so does the need for skilled workers in programming and maintenance. Balancing efficiency with workforce considerations is essential for sustainable progress.

What is an Injection Machine Robot and How Does it Work? - Overview of Injection Machine Robots and Their Applications

| Dimension | Description |

|---|---|

| Type | Robotic Arm |

| Common Applications | Injection Molding, Picking and Placing, Assembly |

| Key Components | Servo Motors, Controllers, End Effectors |

| Benefits | Increased Precision, Higher Efficiency, Reduced Labor Costs |

| Operation Principle | Automated Control of Injection Process, Material Feeding, and Molding |

| Safety Features | Emergency Stop, Safety Sensors, Enclosed Workspaces |

Components of an Injection Machine Robot: Key Parts and Functions

An injection machine robot consists of several key components that work together seamlessly. The most essential part is the injection unit. This unit melts raw plastic and injects it into a mold. Its precision is vital for creating detailed and uniform products.

Next, the clamping unit secures the mold. This unit must apply enough pressure to hold the mold in place during injection. If it fails, the mold could open prematurely, leading to defects in the product. The hydraulic or electric drives in this unit also require regular maintenance to operate effectively.

Another important component is the control system. This system manages all functions, including temperature, injection speed, and cooling time. A user-friendly interface is essential. Operators must understand various settings but can be overwhelmed by complex displays. Training might be inadequate, causing errors. Finally, the cooling system helps to solidify the injected material. Without it, the product may not retain its shape, leading to waste and inefficiency. Each of these components requires careful consideration and ongoing evaluation to ensure optimal performance.

Injection Machine Robot Components and Their Functions

This bar chart illustrates the importance level of various components of an injection machine robot. Each component is rated on a scale from 1 to 10, indicating how critical it is to the overall functionality of the injection machine robot.

The Working Mechanism: How Injection Machine Robots Operate

Injection machine robots are integral to modern manufacturing. They automate the process of injecting materials—often plastics—into molds. This technology increases efficiency and reduces waste. According to a report by Mordor Intelligence, the global injection molding machine market is expected to grow at a CAGR of 3.5% from 2022 to 2027. This growth highlights the importance of robotics in enhancing production rates.

The working mechanism of injection machine robots is fascinating. At their core, these machines use a barrel and screw system. Material is fed into the barrel, where heat melts it. The screw then forces the molten material into a mold. The cooling process solidifies the material, forming a finished product. However, it's not without challenges. Precise temperature control is crucial, as overheating can lead to defects. A study by Technavio noted that nearly 30% of production issues stem from equipment calibration errors.

While these robots offer speed, they require skilled operators for maintenance. Training personnel takes time and resources. According to industry surveys, about 40% of companies report a skills gap in handling sophisticated machinery. This gap can hinder production efficiency and lead to increased downtime. Therefore, companies must invest in both technology and training to fully harness the benefits of injection machine robotics.

Benefits of Using Injection Machine Robots in Manufacturing

Injection machine robots are transforming the manufacturing landscape. These automated systems enhance efficiency and precision. According to a report by MarketsandMarkets, the global market for robotic automation is expected to reach $31 billion by 2025. This growth reflects the increasing reliance on robotic solutions in production lines.

One of the major benefits of injecting machine robots is their ability to minimize human error. By automating tasks, manufacturers can achieve consistent quality and reduce waste. A study from the International Federation of Robotics highlighted that automation can increase productivity by up to 30%. However, reliance on automation also raises concerns about workforce displacement. Finding the right balance between machines and human workers is critical.

Cost savings are another key advantage. Injection machine robots can lower labor costs and increase operational efficiency. The initial investment might be high, but long-term gains can outweigh these expenses. Yet, companies must assess their specific needs and understand that automation is not a one-size-fits-all solution. Some industries may struggle to adapt to rapid technological changes.

Future Trends and Innovations in Injection Machine Robot Technology

The injection machine robot is evolving. Innovations are transforming the production landscape. Future trends focus on automation and efficiency. These robots are becoming smarter, using advanced AI. They learn from data and optimize manufacturing processes.

Integrating IoT capabilities is a key trend. Machines can communicate with each other. This reduces downtime and enhances productivity. However, the reliability of this data is still a concern. Not all systems communicate seamlessly.

Sustainability is also influencing design. Companies aim to reduce waste and energy consumption. New materials are being tested, but results vary. There is still much to explore in this area. Continued research is needed to address challenges. The potential is vast, yet issues remain.