Why is Lifting Supply Essential for Success in Industries?

In the landscape of modern industries, the importance of Lifting Supply cannot be overstated. Industries rely heavily on efficient movement and handling of materials. When lifting equipment is insufficient, delays occur. This can lead to production downtime, affecting overall performance. For instance, a construction site lacking cranes might face project delays. Workers may stand idle, waiting for equipment.

Moreover, the safety of operations hinges on proper lifting supplies. Inadequate tools can result in accidents and injuries. Companies must invest in high-quality lifting gear to ensure the well-being of their employees. Reflecting on this highlights the need for constant evaluation. Are businesses doing enough to assess their Lifting Supply? Often, firms underestimate the ripple effects of poor supply chains.

Ultimately, embracing Lifting Supply as a priority is essential for success. Industries must recognize this interconnection. Optimizing lifting options will boost productivity and safety. It can drive competitive advantage in a challenging marketplace.

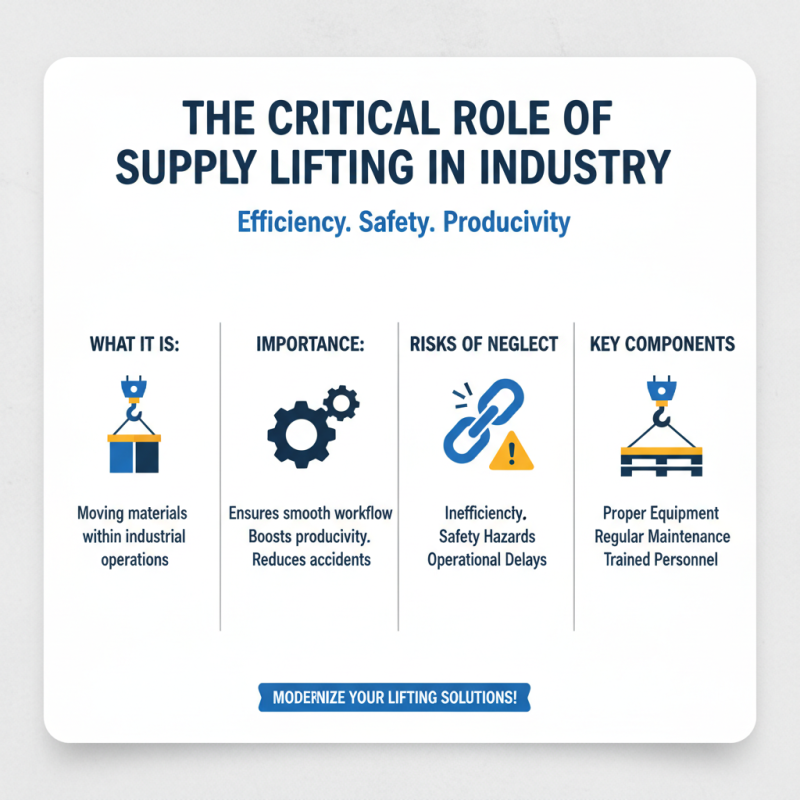

The Role of Supply Lifting in Industrial Operations

In industrial operations, the importance of supply lifting cannot be overstated. This process involves moving materials efficiently. Many industries depend on it to create a smooth workflow. Lifting supplies correctly can reduce accidents and enhance productivity. However, some companies overlook the need for proper lifting equipment. Relying on outdated methods can lead to inefficiencies and safety hazards.

Consider a factory where heavy materials are moved by hand. Such practices slow down production. Workers may struggle and risk injury. Implementing proper lifting techniques can change this. Training employees on the right methods is crucial. Yet, many factories fail to provide adequate training. This creates a gap in knowledge that could be easily filled.

Additionally, having the right equipment is vital. Cranes, forklifts, and lifts improve efficiency. They allow workers to focus on their tasks. However, purchasing and maintaining this equipment requires investment. Some companies hesitate, fearing costs. They miss out on the long-term benefits. Inefficiencies can lead to higher operational costs. Rethinking supply lifting strategies can significantly enhance industrial success.

Understanding Supply Chain Dynamics and Their Impact on Success

Supply chain dynamics play a crucial role in the success of industries. A well-functioning supply chain reduces delays. It ensures that products are available when needed. However, many companies struggle with this aspect. They often face unexpected disruptions. A missing part can halt production lines. This kind of chaos affects profits and customer satisfaction.

Understanding the flow of materials is essential. Many factors influence supply chains. Transportation issues can lead to backlogs. Production schedules may be thrown off balance. Communication between suppliers and manufacturers is key. Misunderstandings can lead to waste and increased costs. Companies need to build strong relationships to avoid these pitfalls.

In reflecting on these dynamics, firms can identify areas for growth. Are they relying too heavily on a single supplier? Diversifying sources can enhance resilience. Each step in the process needs constant evaluation. Supply chain optimization is not a one-time task. It requires ongoing effort and attention to detail. By focusing on these aspects, industries can improve their chances of success.

Factors Influencing the Effectiveness of Supply Lifting

Supply lifting plays a critical role in various industries. The effectiveness of this process depends on multiple factors. Employee training is one such factor. Having skilled workers ensures safety and efficiency when handling materials. Yet, many companies overlook regular training sessions. This leads to accidents and delays, which are costly.

Equipment quality is another influential element. Well-maintained machinery can significantly enhance lifting operations. However, some organizations delay maintenance checks. They focus more on production, often neglecting equipment health. This can result in unexpected breakdowns, which negatively impact productivity.

Finally, communication among team members affects supply lifting. Clear communication helps coordinate tasks, reducing errors. Yet, some teams struggle with miscommunication. This can create confusion during critical moments. Reflecting on these factors reveals areas for improvement in the supply lifting process. Focusing on training, maintaining equipment, and enhancing communication can lead to better outcomes.

Why is Lifting Supply Essential for Success in Industries?

The chart above illustrates the importance level of various factors influencing the effectiveness of supply lifting in industries. Key areas such as efficiency and delivery speed are rated highest, emphasizing their critical role in operational success.

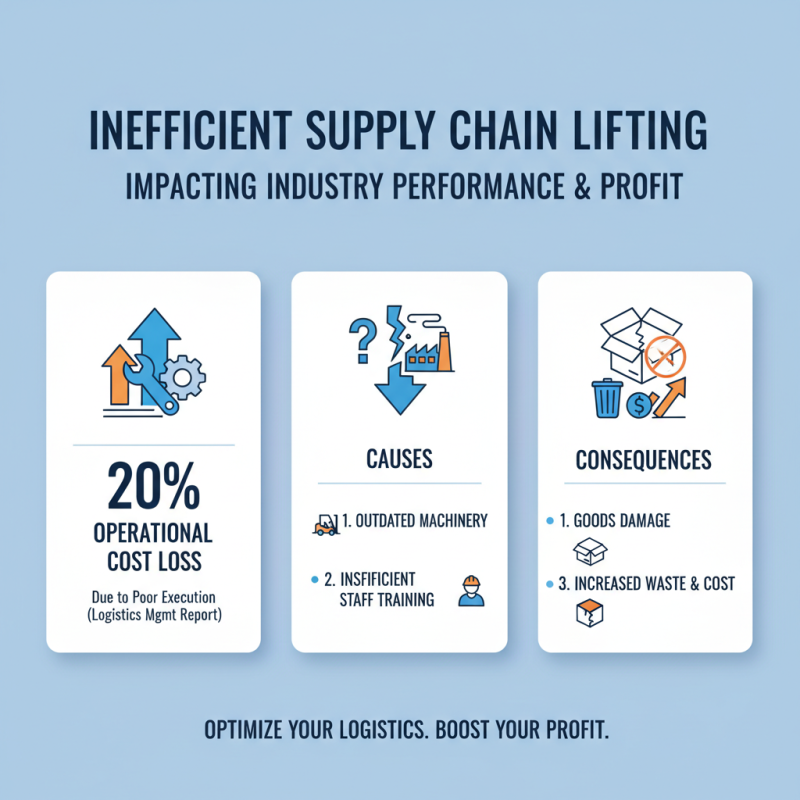

Consequences of Inefficient Supply Lifting on Industry Performance

Inefficient supply lifting can severely impact industry performance. According to a recent report by Logistics Management, poor supply chain execution leads to a loss of around 20% in operational costs. This inefficiency can stem from outdated machinery or insufficient training of staff. Without proper handling, goods may get damaged, leading to increased waste and cost.

In many industries, timely delivery is everything. If companies can't meet consumer demand, they risk losing customers. Data from the Council of Supply Chain Management Professionals reveals that delays can decrease customer satisfaction by 30%. When supply lifting isn't efficient, it creates a bottleneck in operations. This can hold back growth as resources are not utilized effectively. Addressing these issues is crucial for maintaining competitive advantage.

Improving supply lifting processes is not just beneficial; it is essential. Investing in technology can streamline operations. Regular training for workers also plays a key role. However, companies must reflect on their current practices. Are they doing enough? Identification of weak spots can lead to substantial improvements. Without these steps, many may struggle to thrive in today's fast-paced market.

Strategies for Optimizing Supply Lifting for Competitive Advantage

In today's competitive landscape, optimizing supply lifting is crucial for industrial success. Accurate data shows that companies with efficient supply chains can reduce costs by up to 20%. This translates to significant savings. Focus on visibility and collaboration throughout your supply chain. These elements help anticipate disruptions and streamline operations.

One effective strategy is to utilize technology. Implementing advanced analytics can improve demand forecasting. These tools can analyze data in real-time, enhancing responsiveness. Automation may also reduce manual errors. However, the investment in technology can be daunting. Companies must weigh the benefits against costs.

**Tip:** Start small by automating one aspect of your supply chain. Test its impact before scaling.

Another essential strategy is fostering partnerships. Building strong relationships with suppliers can lead to better negotiation terms. It also enhances flexibility in times of need. However, reliance on a few partners can be risky. Diversifying your supplier base is vital to mitigate this risk.

**Tip:** Regularly assess supplier performance. This ensures they meet your evolving needs.

Why is Lifting Supply Essential for Success in Industries? - Strategies for Optimizing Supply Lifting for Competitive Advantage

| Industry | Key Strategy | Impact on Efficiency | Supply Chain Challenges | Potential Solutions |

|---|---|---|---|---|

| Manufacturing | Just-in-Time Inventory | Reduces waste and storage costs | Supplier delays | Establish strong supplier relationships |

| Retail | Dynamic Pricing Strategy | Optimizes stock levels based on demand | Inventory surplus or shortage | Utilize data analytics for demand forecasting |

| Automotive | Vertical Integration | Improves supply control and quality | Dependency on external suppliers | Invest in in-house manufacturing capabilities |

| Pharmaceutical | Cold Chain Logistics | Ensures product integrity during transport | Temperature fluctuations | Implement advanced monitoring systems |

| Food and Beverage | Sustainable Sourcing | Enhances brand reputation and customer loyalty | Supply disruptions due to climate change | Diversify sourcing locations |

Related Posts

-

The Evolution of Lifting Blocks in Global Supply Chains

-

What You Need to Know About Lifting and Handling Equipment Trends in 2023

-

Master the Art of Selecting the Best Lifting Products for Your Business

-

Unlocking Efficiency in Logistics with the Best Lifting and Handling Equipment Techniques

-

Ultimate Lifting Blocks Maintenance Checklist for Optimal Efficiency and Safety

-

Overcoming Lifting Solutions Challenges: Insights and Data for Industry Professionals