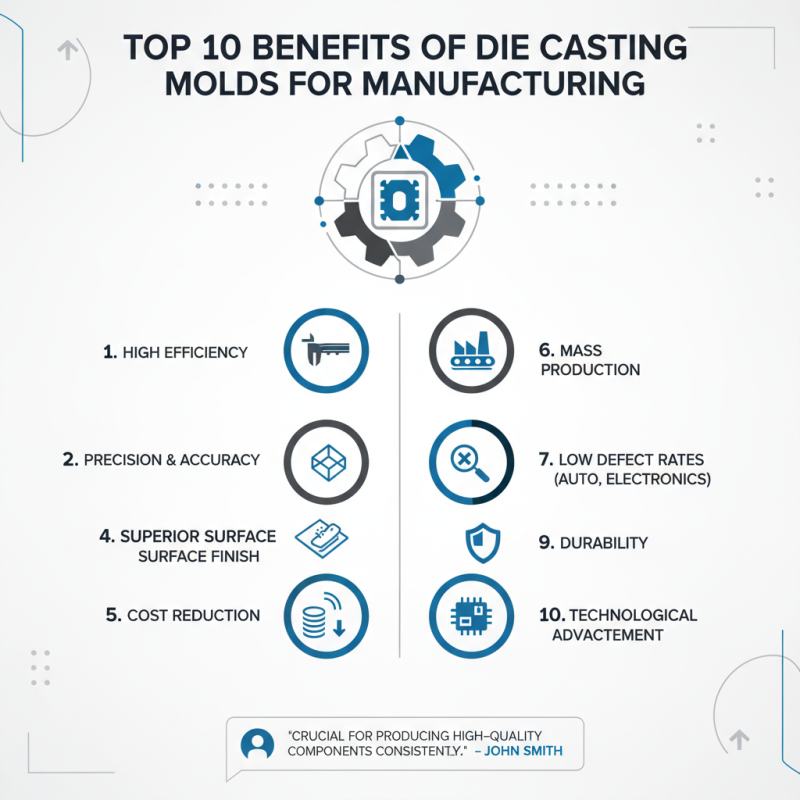

Top 10 Benefits of Die Casting Molds for Manufacturing?

In the world of manufacturing, Die Casting Molds stand out for their efficiency and precision. John Smith, a recognized expert in this field, once mentioned, "Die Casting Molds are crucial for producing high-quality components consistently." This statement highlights the significance of these molds in various industries, from automotive to electronics.

Die Casting Molds enable manufacturers to create complex shapes with outstanding surface finishes. The precision they offer reduces the need for extensive machining and finishing. However, not all molds are created equal. Some can be expensive and require careful maintenance. This poses challenges for smaller manufacturers.

Despite these challenges, the benefits often outweigh the drawbacks. With advancements in technology, Die Casting Molds are becoming more accessible. These molds can produce large quantities while maintaining low defect rates. Therefore, understanding the advantages of Die Casting Molds is vital for any manufacturer aiming for efficiency and quality in production.

Benefits of Die Casting Molds in High-Volume Manufacturing

Die casting molds offer significant advantages in high-volume manufacturing. These molds are known for their durability and precision. They help create complex shapes with , essential for many industries. High production rates are also a major benefit. Die casting can achieve thousands of parts per hour, which is crucial for meeting large orders quickly.

Using die casting molds reduces waste compared to traditional methods. The process allows for high material utilization. However, the initial investment can be high. It's important to evaluate whether the volume justifies the cost. Quality control remains vital in achieving consistent results. Flaws can occur if the process is not monitored properly.

Tips: Regular maintenance of molds is crucial. Keep molds clean to reduce defects. Consider using advanced materials to extend mold life. Training operators is equally important. Skilled workers can spot issues early and prevent defects. Remember, even a slight error can lead to costly setbacks. Always analyze performance data to improve processes. Keeping an eye on these details ensures you reap the full rewards of die casting.

Cost Efficiency of Die Casting Molds Compared to Other Methods

Die casting molds offer significant cost efficiency for manufacturers. Compared to traditional methods like sand casting, die casting reduces material waste. The precise nature of die casting leads to better dimensional accuracy. This precision can minimize the need for secondary machining, which can be costly.

Moreover, die casting allows for high-volume production. Economies of scale kick in quickly, lowering per-unit costs. Manufacturers benefit from faster production cycles, which increases output. However, initial setup costs for die casting molds can be high. This is a point worth reflecting on, as not all projects justify these upfront expenses.

Choosing the right method is crucial. Die casting molds excel in producing complex shapes, yet they require careful design considerations. If the design isn't optimal, costs may soar unexpectedly. Balancing efficiency with careful planning is essential.

Cost Efficiency of Die Casting Molds Compared to Other Manufacturing Methods

Improved Tolerance and Precision in Products from Die Casting

Die casting molds have become increasingly popular in manufacturing due to their ability to create parts with improved tolerance and precision. This process allows manufacturers to produce intricate designs that meet strict specifications. Components made through die casting often exhibit minimal variances, leading to fewer assembly issues and reduced wastage. However, achieving this level of precision requires careful attention to the mold design and material selection.

When molds are crafted with high precision, the final products exhibit consistent surface finishes and dimensional accuracy. This can significantly enhance product performance. In industries like automotive and aerospace, such precision is crucial. Yet, the challenge lies in maintaining this accuracy over repeated cycles. Wear and tear can occur, requiring regular assessments and potential adjustments to the molds. This adds layers of complexity to the manufacturing process.

Nonetheless, the potential for improved precision keeps manufacturers focused on die casting. Regular inspection and high-quality control processes are necessary to maintain standards. Mistakes might arise during production, affecting tolerances. These instances highlight the need for continuous learning and improvement in die casting techniques. Every cycle presents an opportunity to refine the process and innovate further.

Top 10 Benefits of Die Casting Molds for Manufacturing

| Benefit | Description | Impact |

|---|---|---|

| Improved Tolerance | Die casting molds provide high dimensional accuracy, ensuring uniform products. | Reduced need for post-processing and higher product consistency. |

| High Production Speed | Molds allow for high-speed production cycles, increasing output rate. | Lower manufacturing costs and quicker market delivery. |

| Reduced Waste | Die casting uses less material than other processes, minimizing scrap. | More sustainable production and cost savings on raw materials. |

| Complex Geometries | Molds can create intricate shapes that are difficult with other methods. | Expanded design possibilities for engineers and designers. |

| Durability | Die cast products exhibit excellent strength and resistance to wear. | Longer product lifespan and better performance under stress. |

| Flexibility in Materials | Die casting can utilize a variety of metals, including aluminum and zinc. | Adaptability to numerous applications across industries. |

| Consistency | High replication fidelity ensures uniformity in production runs. | Enhanced brand reliability and customer satisfaction. |

| Reduced Assembly Costs | Die casting can create multi-functional components, reducing the need for assembly. | Lower operational costs and efficiency in assembly processes. |

| Improved Surface Finish | Die casting often results in a smooth surface that requires less finishing. | Lower finishing costs and enhanced aesthetic appeal. |

| Energy Efficiency | Modern die casting machines use less energy compared to traditional methods. | Reduction in production costs and environmental impact. |

Material Versatility in Die Casting Molds for Diverse Applications

Die casting molds offer remarkable material versatility, allowing manufacturers to choose from a wide range of materials. Aluminum, zinc, and magnesium are commonly used due to their lightweight and high strength characteristics. According to a report by the American Foundry Society, over 40% of die-cast parts in the automotive industry are made from aluminum. This preference stems from aluminum's excellent thermal conductivity and corrosion resistance.

In addition, the flexibility of die casting molds supports various applications. Industries like automotive, aerospace, and consumer electronics utilize different alloys based on performance requirements. For example, magnesium die casting provides superior strength-to-weight ratios, making it ideal for lightweight components. A study from Market Research Future notes that the aerospace sector is increasing its use of die-cast components by 15% annually, highlighting the trend towards material versatility. However, the initial costs associated with creating custom molds can be significant. This barrier can challenge smaller manufacturers.

Lastly, while die casting molds provide numerous benefits, they might not suit every project. The process can be less effective for complex designs requiring intricate features. Adjusting mold design for specific materials might also lead to production delays. These aspects require careful consideration during the planning phase.

Reduction of Waste and Energy Consumption in Die Casting Processes

The die casting process is gaining attention for its environmental benefits and efficiency. When properly implemented, it can significantly cut waste and reduce energy consumption. Reports indicate that innovatively designed molds can help lower material waste by up to 30%. This reduction not only conserves resources but also cuts costs in the long run.

Energy efficiency is another critical factor in die casting. A study from the Manufacturing Energy Consumption Survey highlights that optimizing die casting molds can decrease energy usage by around 20%. These savings result from the precision of the molds, which lead to faster production cycles and less overheating during operations. It's important to consider that while energy savings are tangible, the initial investment in high-quality molds requires careful reflection.

Despite these benefits, challenges in die casting persist. Many manufacturers still struggle to implement sustainable practices fully. Issues like mold maintenance and the lifespan of materials can lead to inefficiencies. Focusing on education and resources can help address these hurdles and improve overall processes. Balancing cost, efficiency, and sustainability remains a work in progress in the die casting industry.